SCHLICK hollow-cone nozzles atomise pressurised liquids into very fine droplets and thereby provide a large specific surface. The normal spray angle is achieved by bore diameters of

0.1 – 0.5 mm approx. 60°

0.5 – 1.6 mm approx. 70°

1.6 – 20 mm approx. 78°

from 21 mm approx. 80° – 85°

For spray angles smaller or larger than the normal spray angle the nozzle is fitted with a smaller or larger exit hole than that shown in the table. Each air flow rate corresponds to the nominal bore hole. In the same way, the total height of the nozzle can change. A differential pressure at 3 bar is chosen for testing and nominal pressure.

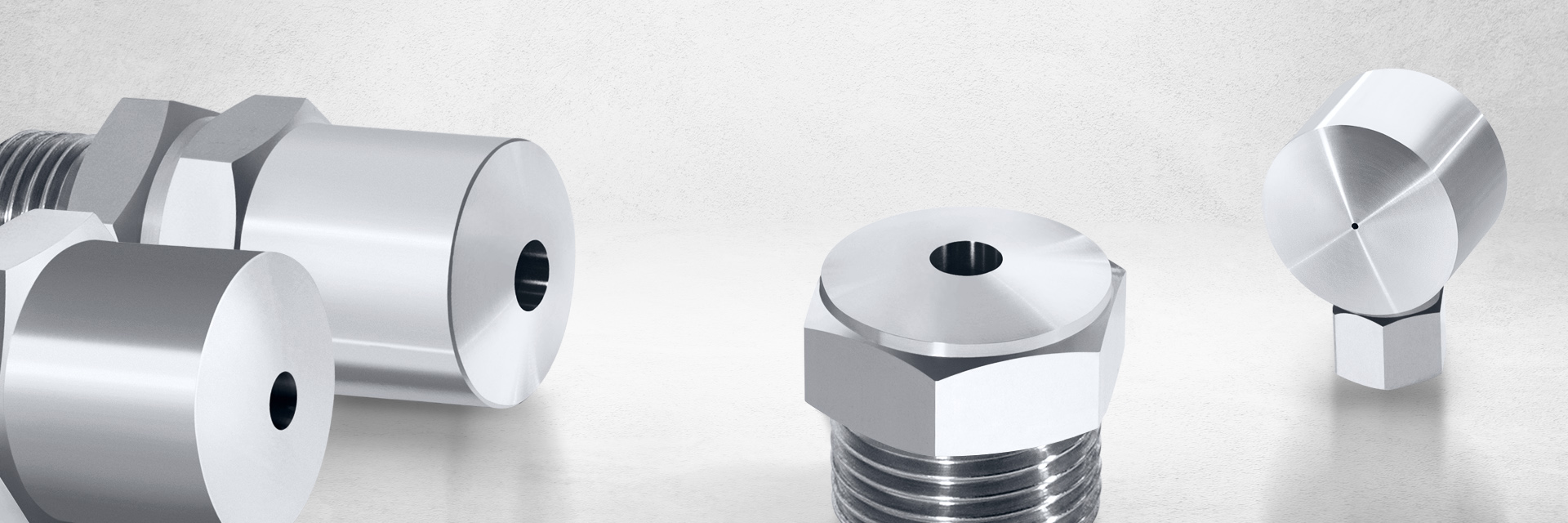

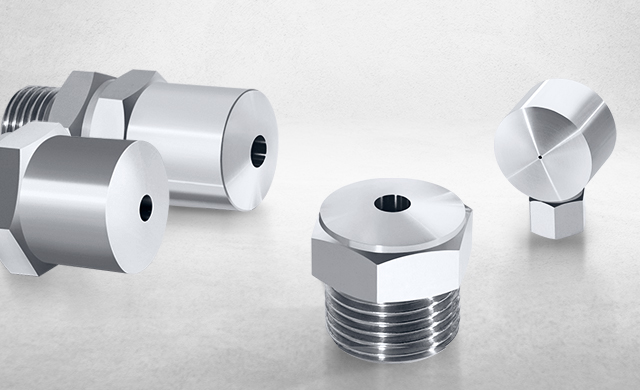

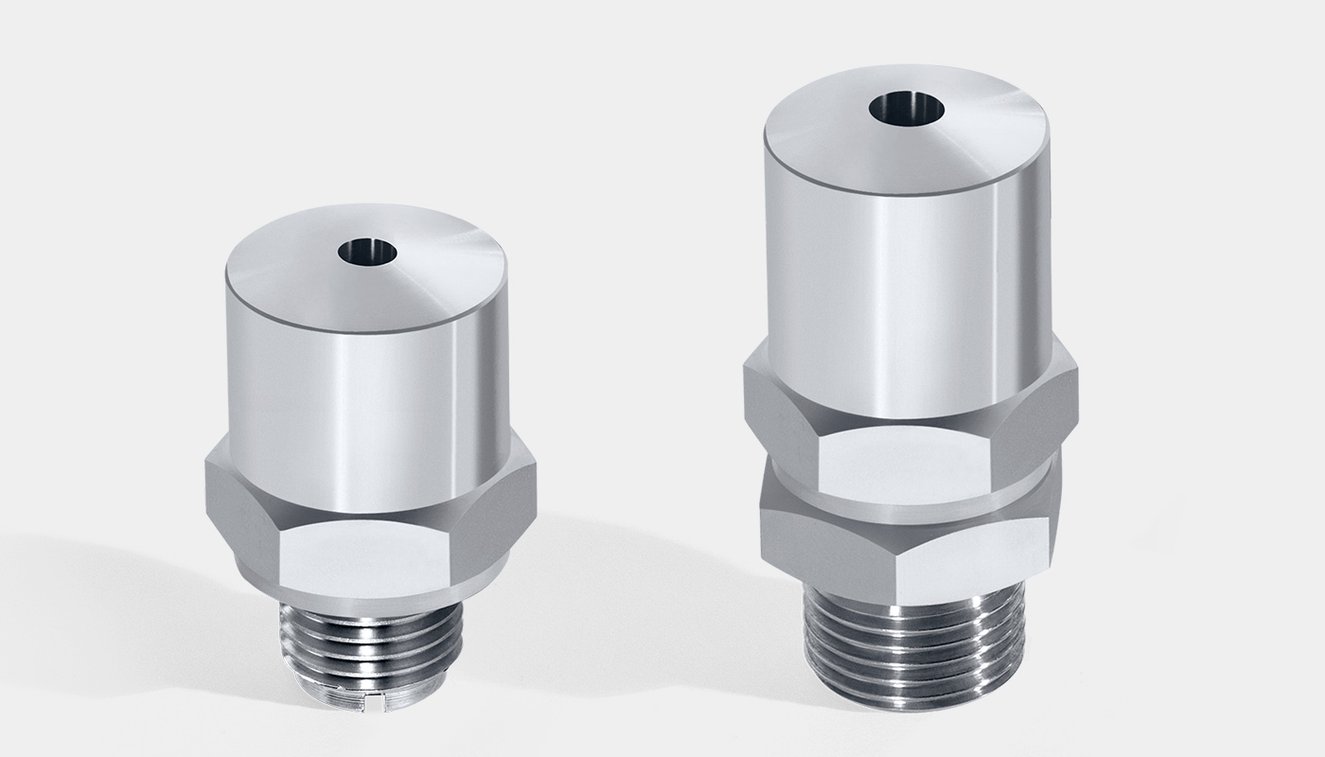

Model 100

The liquid flows tangentially into a swirl chamber and thereby starts to rotate. The energy in the pressurised liquid is converted into rotational energy or kinetic energy. A rotating fi lm of liquid forms around an air core and emerges through the hole as a hollow cone. At the exit of the nozzle the liquid fi lm encounters the surrounding air in a reciprocal reaction and breaks-up into fine droplets. These move away from the nozzle in an axial and radial direction and form a hollow cone.

Model 200

The model 200 has the same characteristics as model 100. The model 200 is fitted with a hexagon bolt on the screw fitting in order to facilitate removal and allow it to be cleaned more easily.

Even hollow cone even with fluctuating liquid pressure

The quality of the atomised spray and the droplet spectrum are related to the diameter of the hole, the pressure, the scatter cone, the density, the viscosity, and the surface tension.

Minimum atomising pressure

0.1 – 0.5 mm Ø: differential pressure = 3 – 6 bar

0.5 – 1.6 mm Ø: differential pressure = 0.5 bar

ab 1.6 mm Ø: differential pressure = 0.1 – 0.5 bar

Droplet size with the same bore hole size

higher pressure = smaller droplets

lower pressure = larger droplets

Droplet size with the same pressure

larger bore hole = larger droplets

smaller bore hole = smaller droplets

dT ~ Ø

Droplet size with the same bore hole size and the same pressure

larger spray angle = smaller droplets

smaller spray angle = larger droplets

dT ~ 1/spray angle

Liquids with higher viscosities and surface areas must be tested for their atomisation with hollow cone nozzles. Compared to water, the fineness of the atomisation is generally coarser.

Materials: Acid-resistant stainless steel, heat-resistant stainless steel, brass, hastelloy, inconel, PP, PTFE, PVC, PVDF, RCH 1000, tantalum, titanium, other materials available on request.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

Hollow cones-nozzles atomise pressurised liquids into very fine droplets and thereby provide a large specific surface.

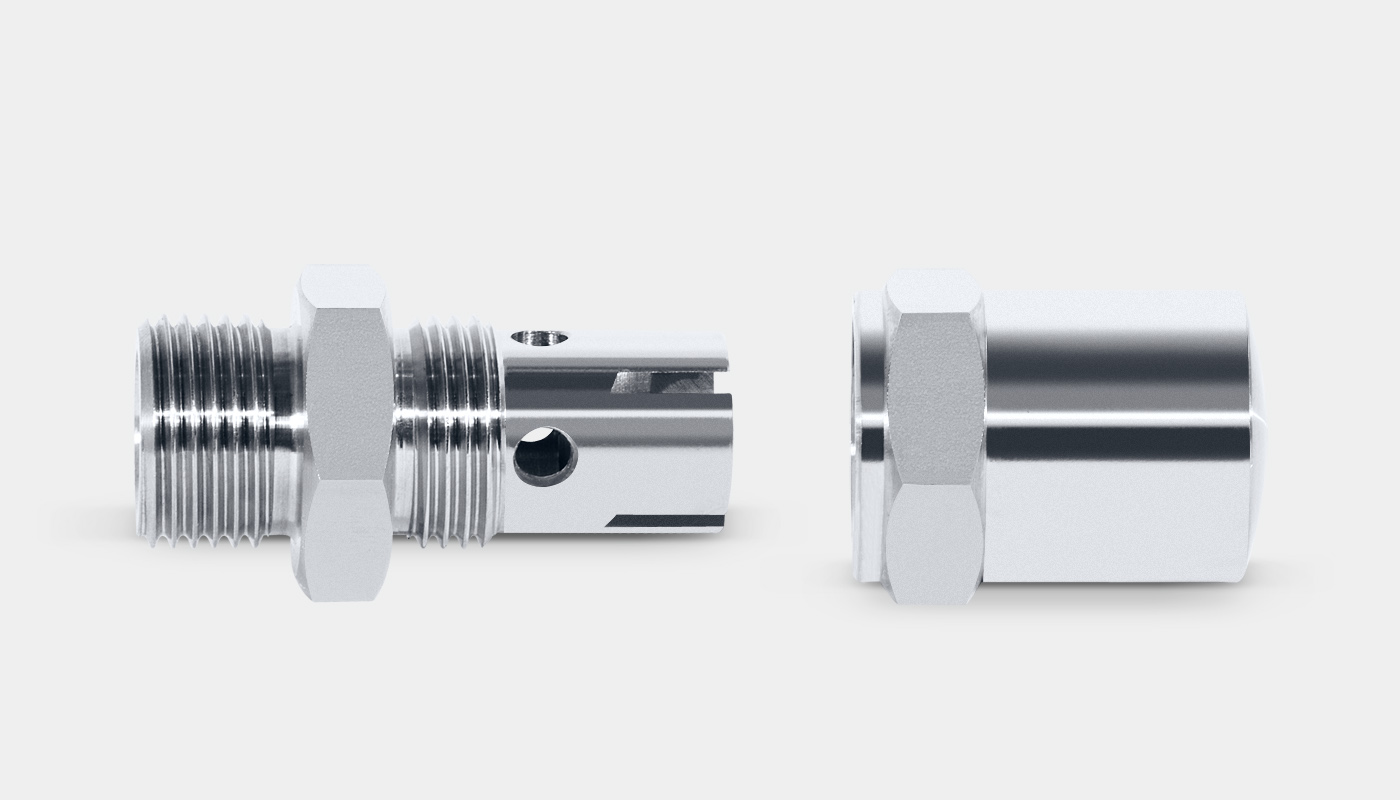

Model 586 for superheated steam cooling is available with a movable swirl body (return valve function), attachment screw G 1/4, G 3/8, G 1/2 or G 3/4.

The custom designed model 100 S15 with heating jacket. This version can be completely disassembled for use in the pharmaceutical/food areas.

The shorted model 103 has the same characteristics as model 100. Using the same oriffice the performance data are still identical.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

In a multitude of industrial fields, such as paper mills, glassworks, cement works, power plants, steel works, waste incineration, etc., cooling process gases in an economical and above all energy efficient way is becoming increasingly important. Evaporative cooling is the most effective way to cool and condition exhaust gases. By cooling the gases, a defined reduction in volume is achieved.

Read moreThe SNCR and SCR procedures were developed for flue gas denitrogenation in order to meet the strict air purification requirements. Injection lances for the defined insertion of the reducing agent are an important component of both processes. These differ in their structural and procedural design depending on the application.

Read moreDuring flue gas denitrogenation, the addition of a reducing agent is used to transform nitrogen oxides into a substance that can be emitted without causing any damage or can be used again. The reducing agent ammonia is increasingly being replaced by innocuous urea. However, urea has a tendency to crystallise during atomisation. When observing the nozzle systems used in urea atomisation, it can be seen that trouble-free operation is not always guaranteed.

Read moreDue to poor or incomplete combustion of the medium, soot is produced, and at the same time the emission values in the combustion chamber increase. With liquid fuels, combustion always takes place in the gas phase: The liquid fuel is first atomised, then vaporised, mixed with air, and finally burned in the gas phase. This article shows how atomisation can be influenced by various special nozzles.

Read moreDue to poor or incomplete combustion of the medium, soot is produced, and at the same time the emission values in the combustion chamber increase. With liquid fuels, combustion always takes place in the gas phase: The liquid fuel is first atomised, then vaporised, mixed with air, and finally burned in the gas phase. This article shows how atomisation can be influenced by various special nozzles ...

Read more

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com