Spray pattern:

smooth-jet (no atomisation)

Spray angle: 0°

Orifices: 0.1 – 30 mm

Capacity: 0.02 – 1000 l/min at 3 bar

– Very precise and effective

– Designed for critical and extremely critical pressure relationships

– Very varied sizes with a capacity up to 1000 l/min

– The familiar and proven SCHLICK technology ensures reproducible results

– Extremely easy installation/de-installation

– Also available as a custom model with a head screw thread

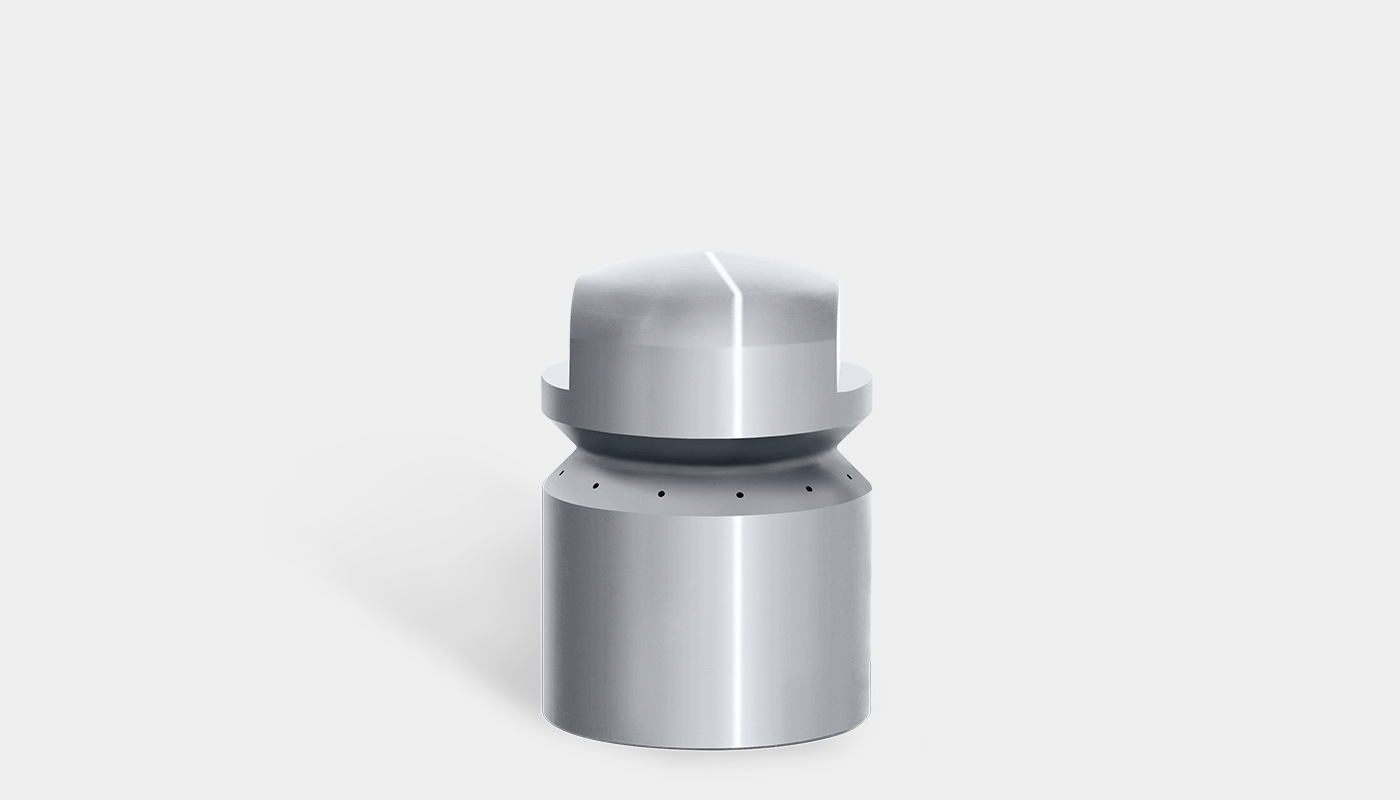

SCHLICK smooth-jet nozzles spray liquids with an extremely precise, far-reaching and smooth jet. The models 629 consists of a single body in one piece with a control cone and a long cylindrical bore hole with a screwed in nozzle exit protector.

Werkstoffe: Acid-resistant stainless steel, heat-resistant stainless steel, ebonite, brass, PVC, tantalum, titanium, teflon, other materials available on request.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

The special designed model 629 S21 with integrated ball joint allows constant movement of the nozzle exit in all directions.

Model 618 with bore holes towards the front. The quantity and diameter of the bore holes are individually specified.

Model 629

Model 629 consists of a one-piece body with a guide cone and a long cylindrical bore with screwed-in orifice protection.

Model 629 K

For fixing the nozzle into containers, flanges or pipes, this variant of the model 629 is equipped with a screw thread.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

Extruders are plant systems frequently used within pharmaceutical manufacturing and food production to mould substances or modify them physically. When it comes to introducing precise amounts of additives, there are nozzles available which enable you to introduce low quantities and make precise, reproducible additions. (Only german version.)

Read moreProfessional spraying in industrial wood machining, especially the production of boards, is gaining increasingly in importance. This is not just because of the increasing cost of energy and raw materials; it is also because increasingly high demands for quality in the manufacture of wooden boards encourage the demand for suitable processes and possibilities, in order to apply liquids as homogeneously as possible onto prepared base materials.

Read more

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com