SCHLICK dosing systems have been specially developed for installation in spray systems with pulsed operation.

They enable precise dosing without any dripping or idling whatsoever.

Industry sectors where substances need to be physically modified with precision regularly use these systems.

Precise. Precise and reproducible dosing of very small quantities.

Safe. Entirely free from dripping or idling during use.

Straightforward. Hassle-free and easy assembly/disassembly and cleaning.

Customised. Specific designs for all sectors/applications.

Original. Consultation, engineering, production and testing from SCHLICK.

The quantity to be added is regulated via the bore of pressure-controlled nozzles and the available liquid differential pressure. In depressurised conditions, the dosing system is sealed via spring tension.

The opening pressure depends on the spring tension, which can be defined by the manufacturer according to customer requirements, or adjusted in individual model variants via an adjusting screw.

In nozzle models with pneumatic open/close control, the extremely precise opening and closing times are controlled pneumatically. Cleaning needles can be used, depending on the model variant.

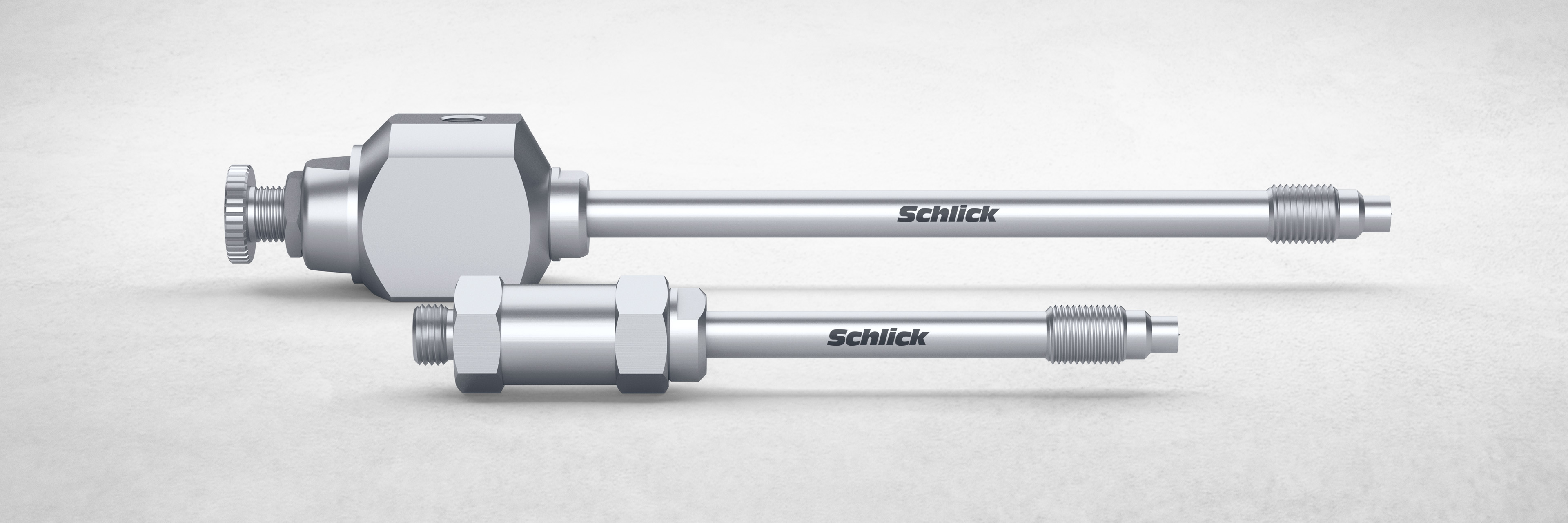

Model 1055 – high flexibility thanks to individual adjustment

The 1055 model features lateral liquid supply, which enables continuous adjustment of the opening pressure (up to max. 6 bar) thanks to its specially designed adjusting screw. This means that the flow can be individually adjusted and controlled. The valves are opened and closed by raising or lowering the liquid pressure. The closing pressure is about 0.5 – 1 bar below the opening pressure. Simple assembly/disassembly for cleaning or servicing by hand.

Manufactured in stainless steel 1.4404, acid-resistant stainless steel 1.4571 or brass.

Bores of up to max 3.0 mm are available. Flow rate is subject to the bore diameter, pressure and media properties.

Model 1056 – powerful even with highly viscous media

Thanks to its straight, centric liquid supply, the 1056 model is particularly well suited to atomising highly viscous liquids or media with a high solid content. The standard performance ranges from 0 – 5 l/min at a nominal pressure of 3 bar. The construction is not only extremely stable, but is also low-maintenance due to its sophisticated construction. The pressure spring responsible for opening and closing the liquid supply can be designed to handle pressure of up to 9 bar. This means it can be used for a wider range of media.

Manufactured in stainless steel 1.4404, acid-resistant stainless steel 1.4571 or brass.

Bores of up to max 3.0 mm are available. Flow rate is subject to the bore diameter, pressure and media properties.

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com