Use this perfect nozzle technology right from the smallest batch size

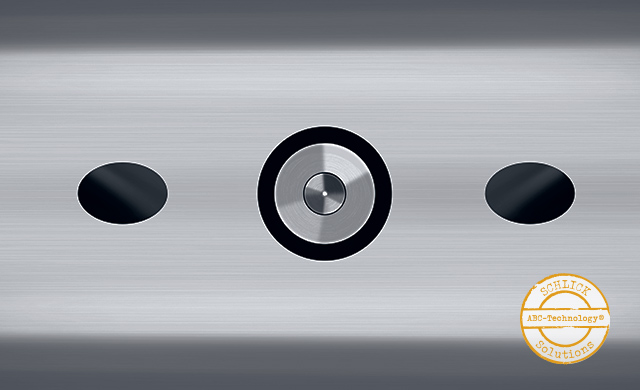

The SCHLICK ABC-Technology® design offers optimum operating security within coating-facilities. The so-called „Anti-Bearding Cap (ABC)“, crucially prevents turbulence in the area of the air cap and the nozzle exit, by means of its novel rounded shape. Perfect up- and downscaling: Using the complete SCHLICK ABC-Technology® the specially designed ABC nozzles support capacities from 1 to 180 g/min. The nozzles have been developed for drums sizes from 8.5” to 24".

Perfect 'beardless' spraying

Build-up, caking, „bearding“ or clogging of the nozzle exit are prevented as far as possible in this way. Interruptions to the coating process, as a consequence of cleaning work on the nozzle, are almost completely omitted. The SCHLICK ABC spray features an exceedingly homogenous liquid distribution, in a simultaneously very fine, uniform and reproducible drop size distribution.

The ideal ABC spray is characterised by a very even ellsis. This is achieved by means of a balance between the pressures – the forces of the atomising air (AA) and the pattern air (PA).

In the following figure, the various specifications of the different sprays and their characteristics are depicted by removing 200 mm from the nozzle exit.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com