Plug & Spray

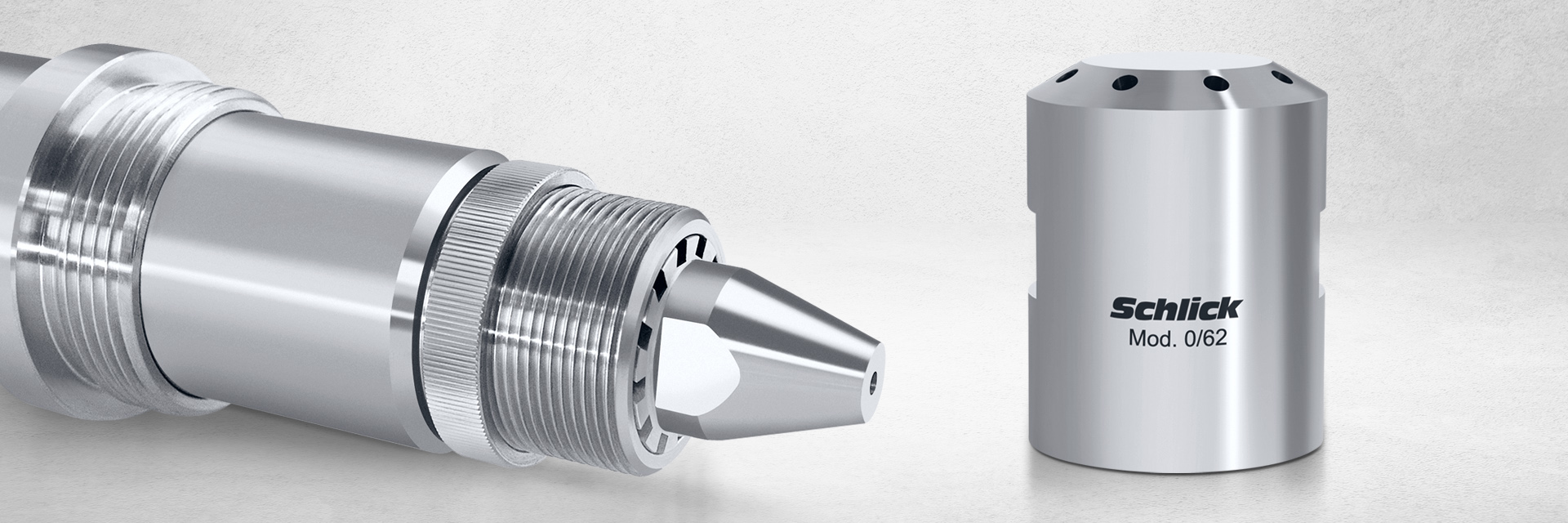

An easy and therefore cost-effective modification to the existing nozzle systems was decisive for the new SCHLICK design. By simply changing the air cap the internal-mixing model can be updated.

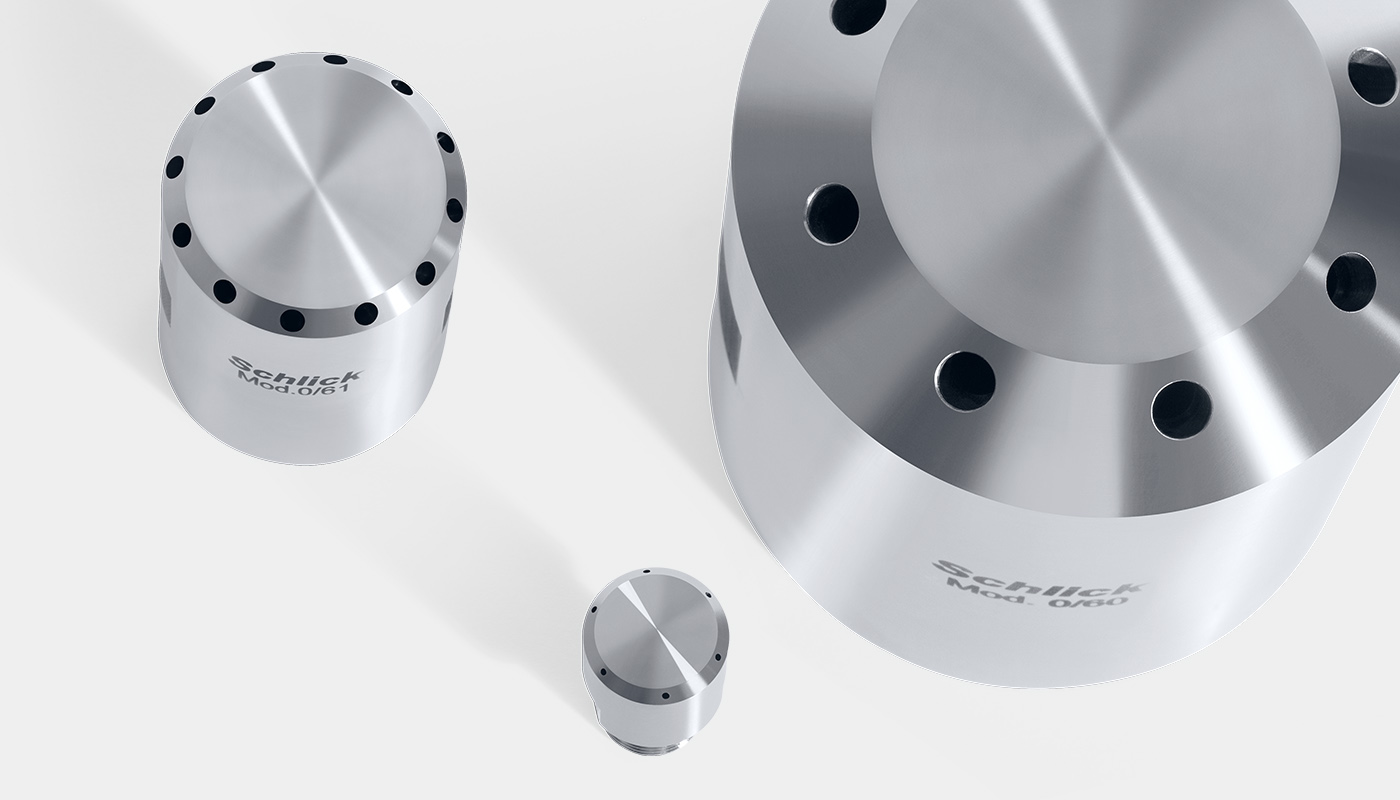

The liquid jet flows through the central hole into an optimised mixing chamber. When this reaches the specially devised cone it is distributed and is broken down into single droplets by the swirled atomised air. The two-phase mix then leaves the air cap through the customer-specified bore holes. Despite a very low speed impulse the SCHLICK model series 0/64-0/60 can achieve a scatter cone of approx. 70° through the specific hole arrangement. That's how the SCHLICK internal mixing cap achieves a very fine atomisation and offers greater area coverage than comparable models.

The result: an area coverage up to 900 percent compared to external mixing models.

Customized bore sizes are possible starting from 0.3 mm upwards in 0.1 mm steps.

Materials: Acid-resistant stainless steel, heat-resistant stainless steel, titanium, tantalum, carbonide, hastelloy, inconel, other materials available on request.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

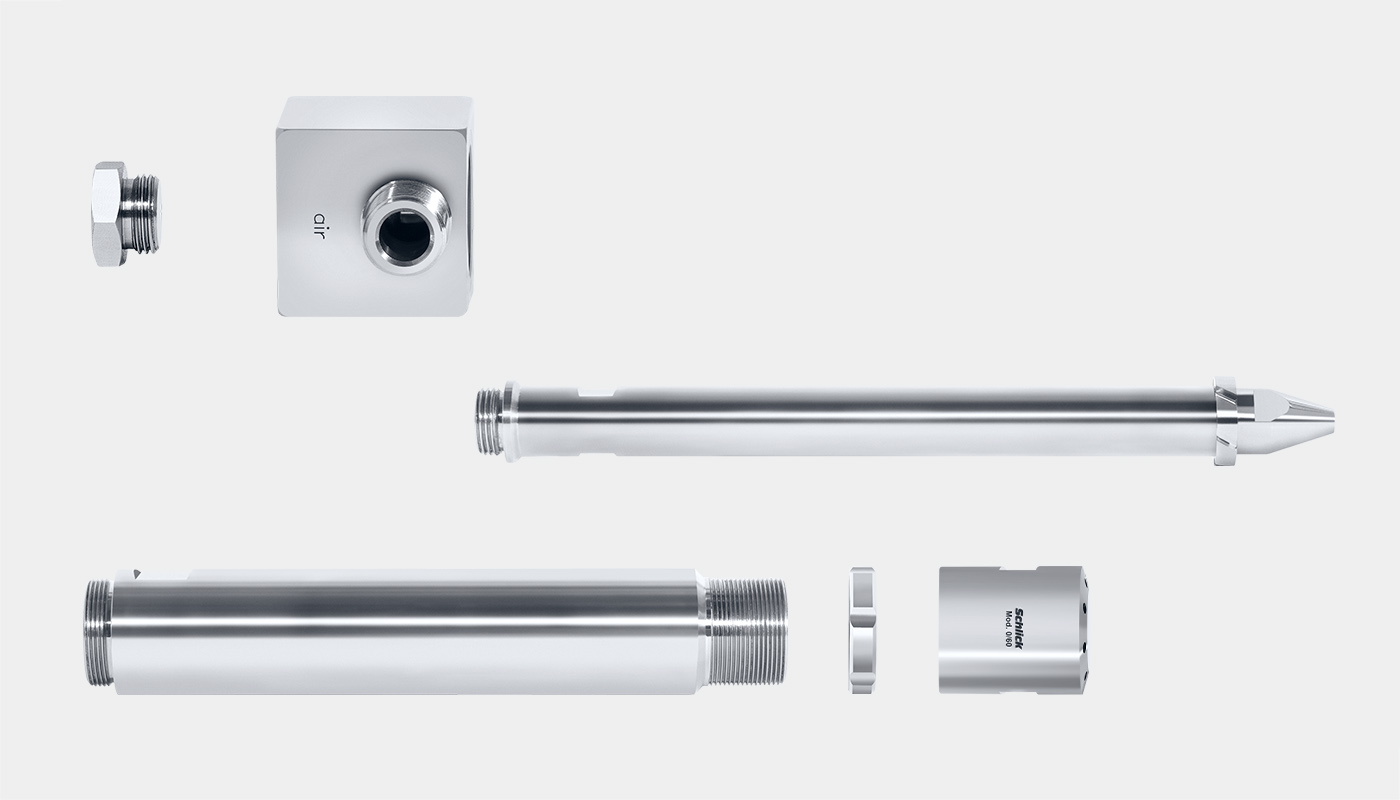

Form 0

Basic model with dummy plug. Designed for the atomisation of liquids that are either siphoned or fed by gravity at a slight gradient. For homogeneous distribution on large specific surfaces.

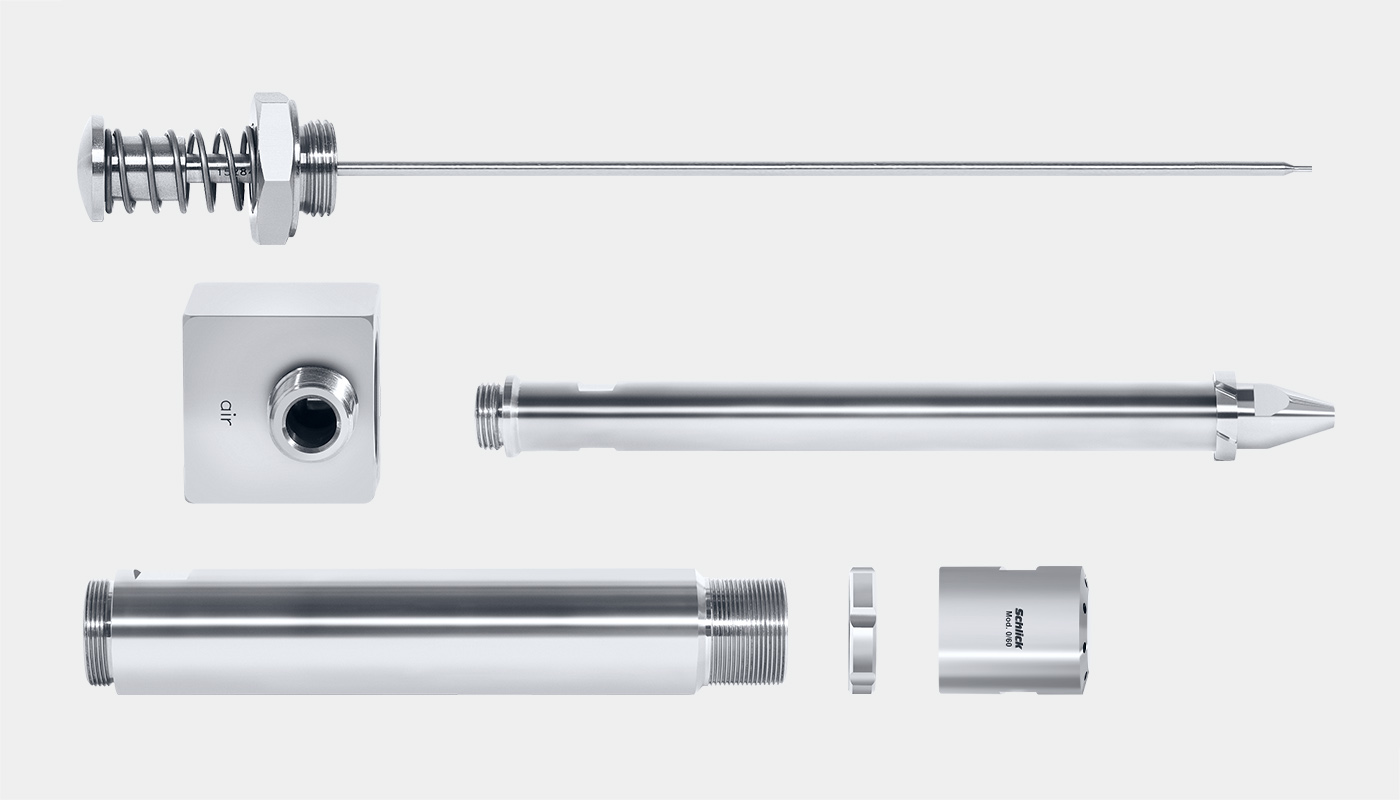

Form 3

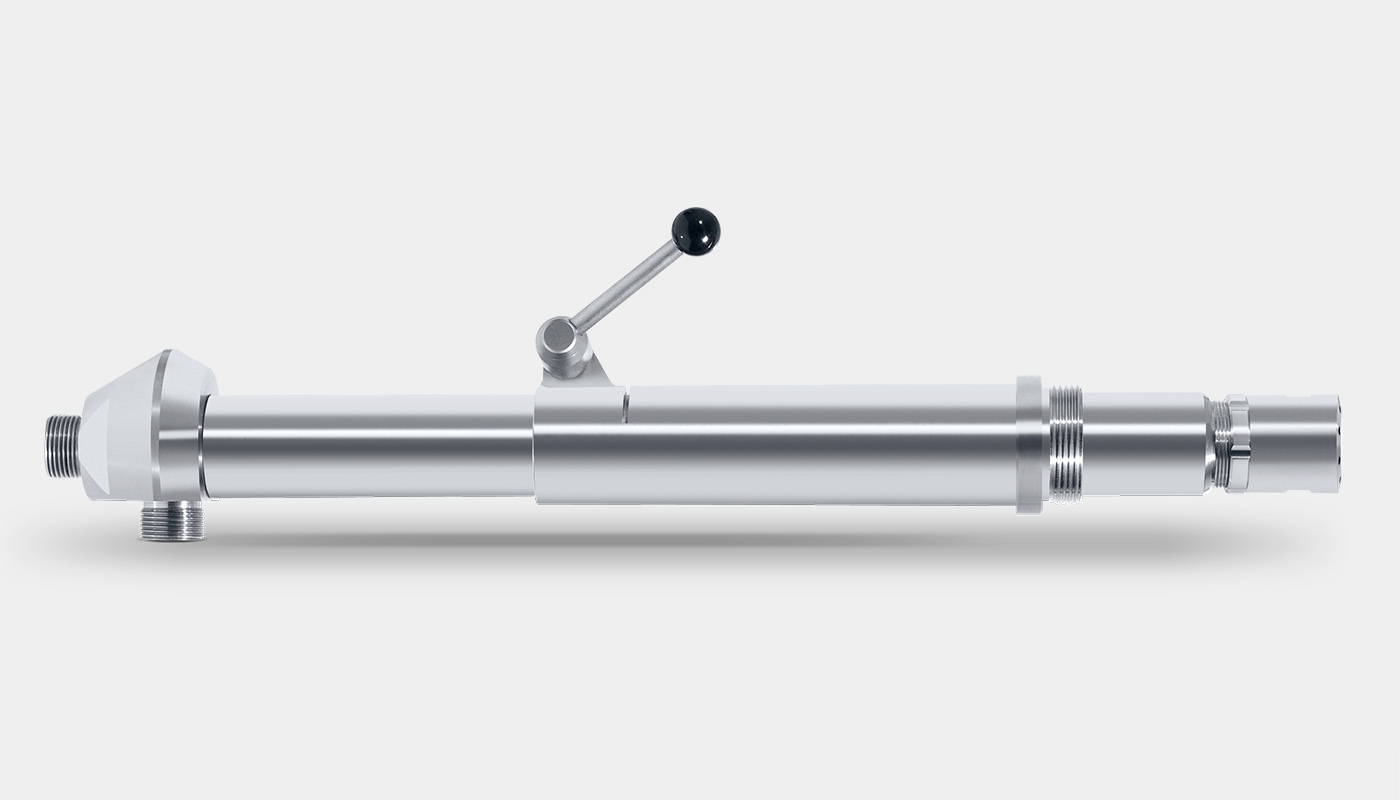

Supplied with manual operated cleaning needle. For fast nozzle orifice cleaning during operation. Designed for the atomisation of sticky, impure, or highly viscous liquids, etc.

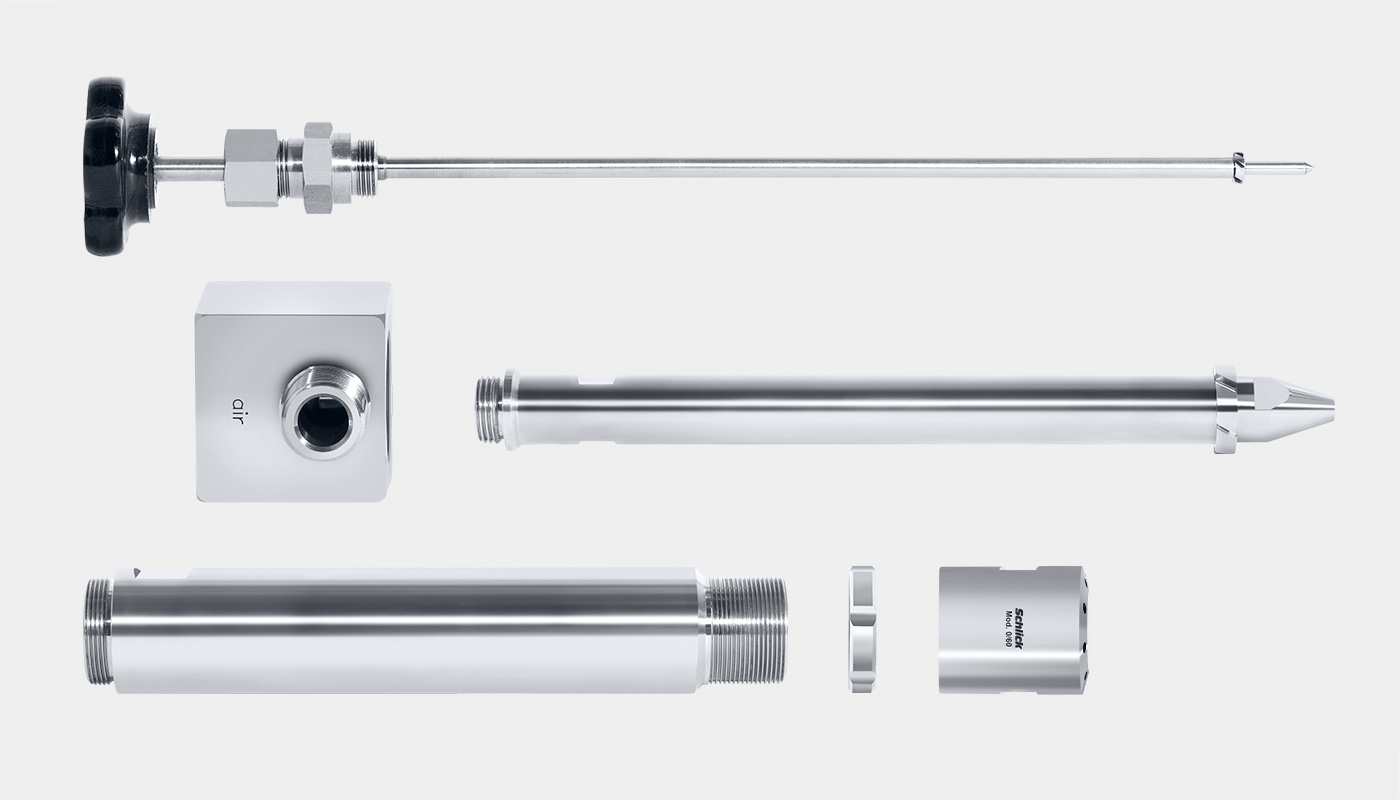

Form 4

Version with a liquid flow control needle. This design is particularly suitable for applications or atomisation tasks with highly variable flow rates.

The patented internal mixing modul system range 0/64-0/60 increases an area coverage up to 900 percent compared to external mixing models.

Custom designed model 0/61 form 6 with clamping unit. Individual shaft lengths. Clamping also possible with a flange or other plant fittings.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

Professional spraying is gaining much more in importance as a technique, especially in the production of MDF board, as it is a very helpful way of reducing costs while maximising quality at the same time. With its newly developed SCHLICK Blowline, Düsen-Schlick is setting new benchmarks for the widely used technique of blowline gluing.

Read moreFor decades, Düsen-Schlick has been supplying systems manufacturers and cigarette producers with process-optimised atomisation technology. Moistening and flavouring are core processes in the primary stage of tobacco processing. These are ultimately responsible for the flavour and quality of the final product. Properly measuring flavouring additives and uniformly moistening leaves and ribs ensure optimum cutting and drying properties. This also creates benefits for the downstream (secondary) stage of cigarette production.

Read moreThe SNCR and SCR procedures were developed for flue gas denitrogenation in order to meet the strict air purification requirements. Injection lances for the defined insertion of the reducing agent are an important component of both processes. These differ in their structural and procedural design depending on the application.

Read moreDuring flue gas denitrogenation, the addition of a reducing agent is used to transform nitrogen oxides into a substance that can be emitted without causing any damage or can be used again. The reducing agent ammonia is increasingly being replaced by innocuous urea. However, urea has a tendency to crystallise during atomisation. When observing the nozzle systems used in urea atomisation, it can be seen that trouble-free operation is not always guaranteed.

Read moreDue to poor or incomplete combustion of the medium, soot is produced, and at the same time the emission values in the combustion chamber increase. With liquid fuels, combustion always takes place in the gas phase: The liquid fuel is first atomised, then vaporised, mixed with air, and finally burned in the gas phase. This article shows how atomisation can be influenced by various special nozzles ...

Read more

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com