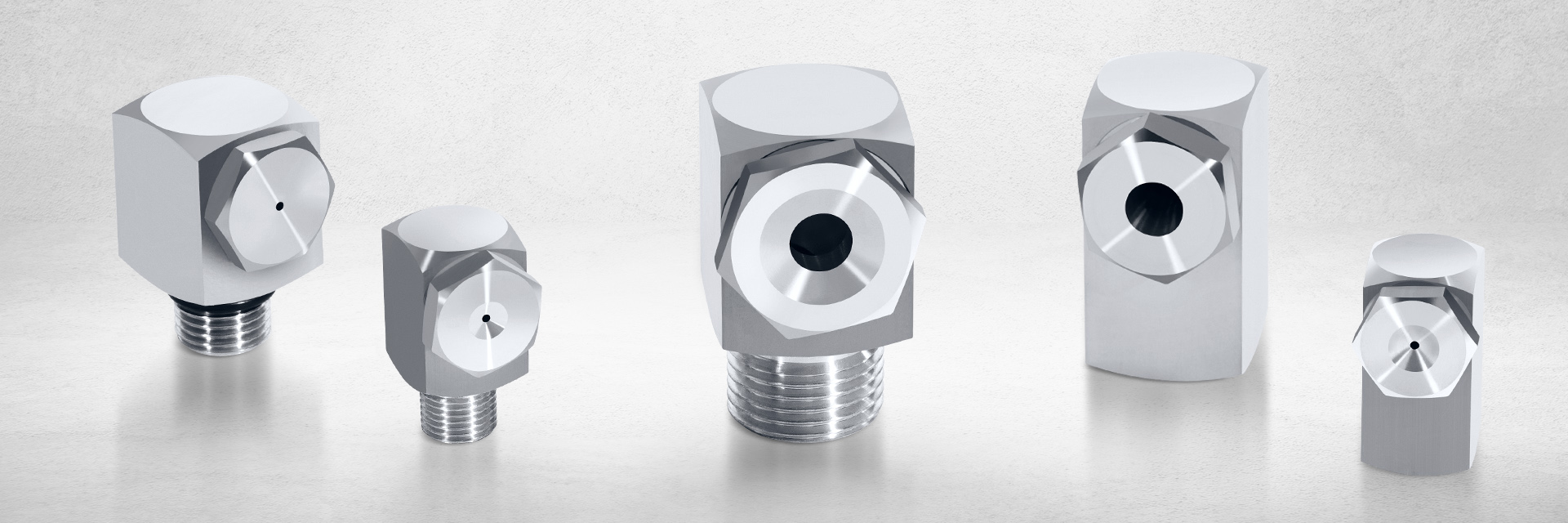

SCHLICK hollow-cone nozzles atomise liquids under pressure into finest droplets having a large specific surface. The liquid flows tangentially into a swirl chamber and thereby starts to rotate. The energy in the pressurised liquid is converted into rotational energy or kinetic energy. A rotating film of liquid forms around an air core and emerges through the hole as a hollow cone. At the exit of the nozzle the liquid film encounters the surrounding air in a reciprocal reaction and breaks-up into fine droplets. These move away from the nozzle in an axial and radial direction and form a hollow cone.

For spray cones smaller or larger than the normal spray cone the nozzle is fitted with a smaller or larger exit hole than that shown in the table. In each case the through flow corresponds to the nominal bore hole.

The nozzles simply consist of one nozzle body and one exchangeable exit unit. Through the specially developed liquid intake no further fittings are necessary, which means that blockages are practically eliminated.

SCHLICK models 400 and 401 are especially well suited for right-angled fitting and are available with external screw thread (model 400) or internal screw thread (model 401). Different sizes and various materials complement this range.

Materials: Acid-resistant stainless steel, heat-resistant stainless steel, brass, hastelloy, inconel, PP, PTFE, PVC, PVDF, RCH 1000, tantalum, titanium, other materials available on request.

The SCHLICK cleaning set includes all necessary tools for preservation of nozzle parts

– 3 x brush (ø 8, 14 and 20 mm)

– 1 x double cylindric-brush

– 1 x o-ring-tool (stainless steel)

– 1 x spoon-spatula (stainless steel)

– 1 x thread-cleaningbrush

– 1 x magnifying glass

– 3 x synthetic lubricating grease

Synthetic lubricating grease

for valves and fittings with elastomer seals, compatible with EPDM and conforming to FDA. Can be dispensed in very small doses using special injection devices.

Brochure "SCHLICK Technology – Overview"

The product overview shows all essential things at first glance

Consultation, engineering, production and testing.

At SCHLICK, you get everything from one source.

The ideal solution for your application.

Phone +49 9565 9481-0

Mail info(at)myschlick.com

Hutstraße 4 | 96253 Untersiemau/Coburg

Telefon: +49 9565 9481-0

Mail: info(at)myschlick.com